Lean Manufacturing Things To Know Before You Get Thiss

Wiki Article

Things about Lean Manufacturing

Table of ContentsThe Definitive Guide for OemOem - QuestionsNot known Factual Statements About Lean Production Additive Manufacturing Fundamentals ExplainedMore About Additive ManufacturingNot known Incorrect Statements About Mfg

The text on this page is an example from our complete White Paper 'Injection Moulding for Customers' - * Sample message * - for complete guide click the download button over! Introduction This overview is meant for people who are aiming to source plastic mouldings. It provides a much needed insight right into all that is involved with creating plastic components, from the mould device needed to the moulding process itself.If you want to discover further, the overview covers kinds of mould tools, as well as special completing procedures such as colours & plating. Words that are underlined can be found in the glossary in the appendix ... Part I: Moulding: The Fundamentals The Advantages of Shot Moulding Plastic shot moulding is a very precise process that supplies a number of benefits over various other plastic processing techniques.

Accuracy is excellent for very intricate parts. You can hold this moulding in the hand of your hand and also it has employers, ribs, metal inserts, side cores and also openings, made with a gliding shut off function in the mould device.

Some Known Factual Statements About Lean Production

Not known Facts About Die Casting

from material feed Product melting; material injectionProduct cooling time cooling down ejection to the re-closing of the mould tool ready for prepared next cycleFollowing Draft angles - The wall surfaces of a moulded component should be somewhat tapered in the direction in which the part is ejected from the mould tool, to enable the component to be expelled quickly.Ejector stroke - The pressing out of ejector pins to expel the moulded part from the mould tool. Ejector stroke speed, length as well as timing requires to be carefully regulated to avoid damage to the ejectors and also mould tool, but at the exact same time make the moulding cycle as brief as possible.

The Main Principles Of Hon Hai Precision

Ribs - When a plastic component has slim wall surfaces, ribs are added to the design to make the thin walls stronger Side cores - Side activity which produces a function on a moulded component, at an opposing angle to the normal opening instructions of the mould device. manufacturing industries. The side core requires to be able to withdraw as the plastic component can straight from the source not be expelled otherwise.

Wall surfaces - The sides of a moulded component The message on this page is a sample from our full White Paper 'Shot Moulding for Buyers'.

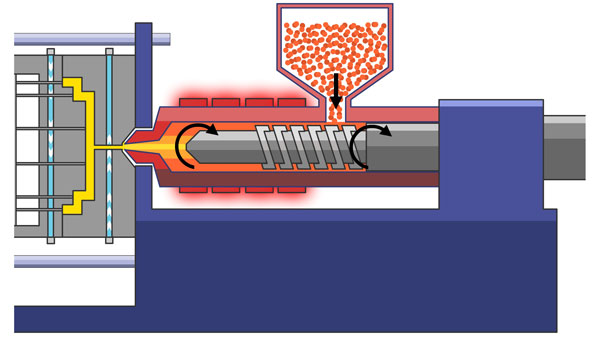

Injection moulding is extensively utilized for producing a range of parts, from the tiniest components to whole body panels of cars. Injection moulding utilizes a special-purpose maker that has three parts: the injection system, the mould and the clamp.

How Manufacturing can Save You Time, Stress, and Money.

Refine attributes [modify] Injection moulding utilizes a ram or screw-type plunger to compel liquified plastic or rubber material right into a mould dental caries; this solidifies into a shape that has complied with the contour of the mould. It is most typically used to refine both thermoplastic and also thermosetting polymers, see here with the quantity used of the previous being substantially higher.: 13 Thermoplastics are prevalent as a additional resources result of features that make them extremely suitable for shot moulding, such as ease of recycling, convenience for a variety of applications,: 89 and capability to soften and flow on home heating.In multiple dental caries moulds, each cavity can be the same and create the same components or can be one-of-a-kind as well as create multiple various geometries throughout a single cycle.

The screw delivers the raw material onward, blends as well as homogenises the thermal as well as viscous distributions of the polymer, and decreases the called for heating time by mechanically shearing the material as well as adding a significant amount of frictional home heating to the polymer. The material feeds forward with a check valve as well as gathers at the front of the screw right into a volume understood as a shot. When enough product has collected, the material is compelled at high stress as well as speed into the part forming cavity. The precise quantity of contraction is a feature of the resin being made use of, and can be relatively foreseeable. To stop spikes in pressure, the procedure usually utilizes a transfer placement representing a 9598% complete dental caries where the screw shifts from a constant speed to a consistent stress control.

Everything about Hon Hai Precision

The packaging pressure is used up until the gate (dental caries entrance) solidifies. Due to its tiny dimension, the gate is generally the first location to solidify with its whole thickness.: 16 Once the entrance strengthens, no more product can go into the tooth cavity; appropriately, the screw reciprocates and also obtains material for the following cycle while the product within the mould cools so that it can be expelled as well as be dimensionally steady.Report this wiki page